Anatomy of a first client sign making project.

Just before thanksgiving, a friend saw some of my sign work on instagram and approached me about making a sign for her husband. My first commission! This was both exciting and nerve wracking, as I respect them both a great deal and did not want to disappoint. I was also confused about what would be fair to charge- I didn't want to lose money on a favor, but like so many creators, I know that imposter syndrome can be a real thing.

Having spent the past 25 years doing graphic design, I did have a couple insights that helped though. First, don’t feel guilty about charging money for your work, even with friends and family. People respect things they pay for more than favors they get for free. Second, get things in writing! Not to be all lawyer-like, but more to make sure you both are roughly on the same page, expectation wise.

THE ESTIMATE

The process starts by listening. Once I had a pretty good idea of what I thought she wanted, I drafted up an estimate, starting with a brief overview of what I would be delivering, before getting to the fun part.

Materials

Based on the deliverable, I sat down at a browser and got costs for materials at my local Menards and on Amazon. Now, many established makers or businesses will charge a markup- and thats fair- since this was a friend and I made the decision to just pass them through at cost. One thing that I did that I am pretty proud of though is charge a “shop fee” of 10%. I remembered seeing this ambiguous line on a bill from a mechanic and thinking it sucked, but being on the other side, it makes soooo much sense. There are tons of little things like glue, wire, finishing rags, brush cleaner, etc that get consumed in making a project that don’t merit their own line item. The shop fee is an awesome little tool to help recover some of that.

Labor

The good news- my material estimate was pretty dead on. The bad news- my labor rate worked out to about, I dunno, probably .25 an hour, haha. But much of that was me experimenting with techniques I had never done before and working with materials I’ve never used. If I were a comnpentent tradesperson, the labor estimate would probably be not that far off. But yeah, if you’re just getting started at this, expect to take a bath in this area.

Terms and stuff

Pretty simple- get half up front, and half on completion. In this case, it worked out nicely that half was enough to cover materials. In the future I wouldn’t be surprised if materials and labor kept somewhat in lockstep because that makes things clean and easy. I also make it super easy for the client to pay me in whatever manner they want.

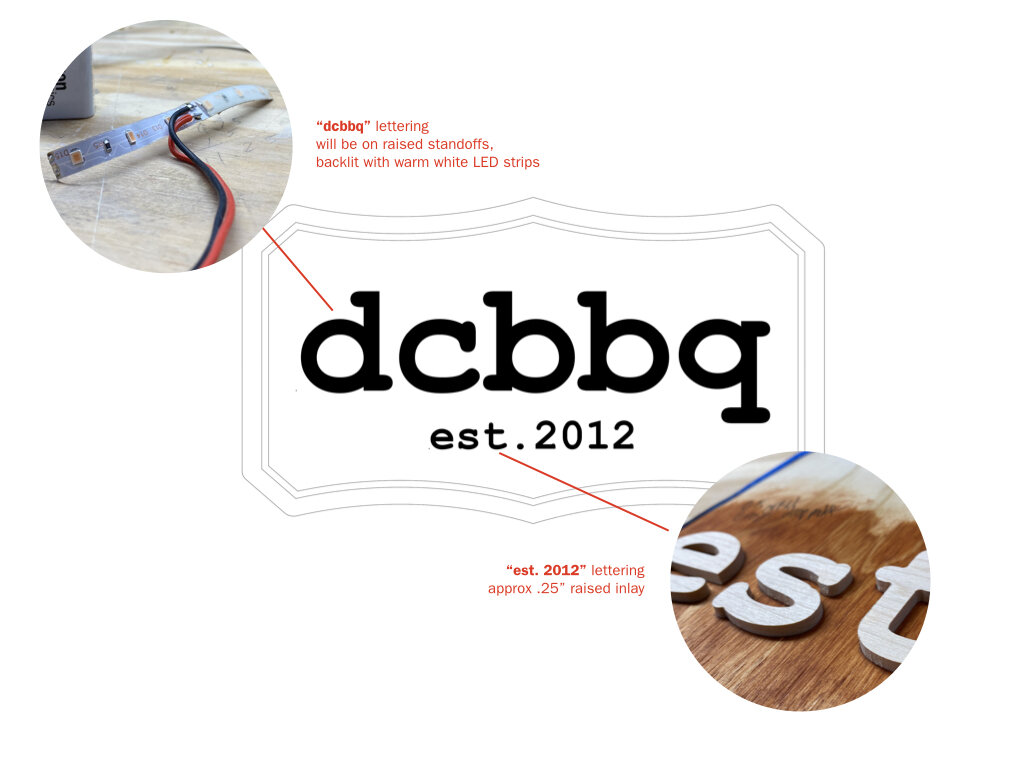

INITIAL DESIGN PRESENTATION

With deposit in hand, it’s off to the races. I promised the client two look and feels, so I sat down in illustrator and sketched out a couple ideas, and assembled them into a presentation. The presentation also showed the lighting idea, my color thoughts, and a couple production design considerations. They were well received and I was given the thumbs up to proceed with Option 2 without any revisions. Awesome!

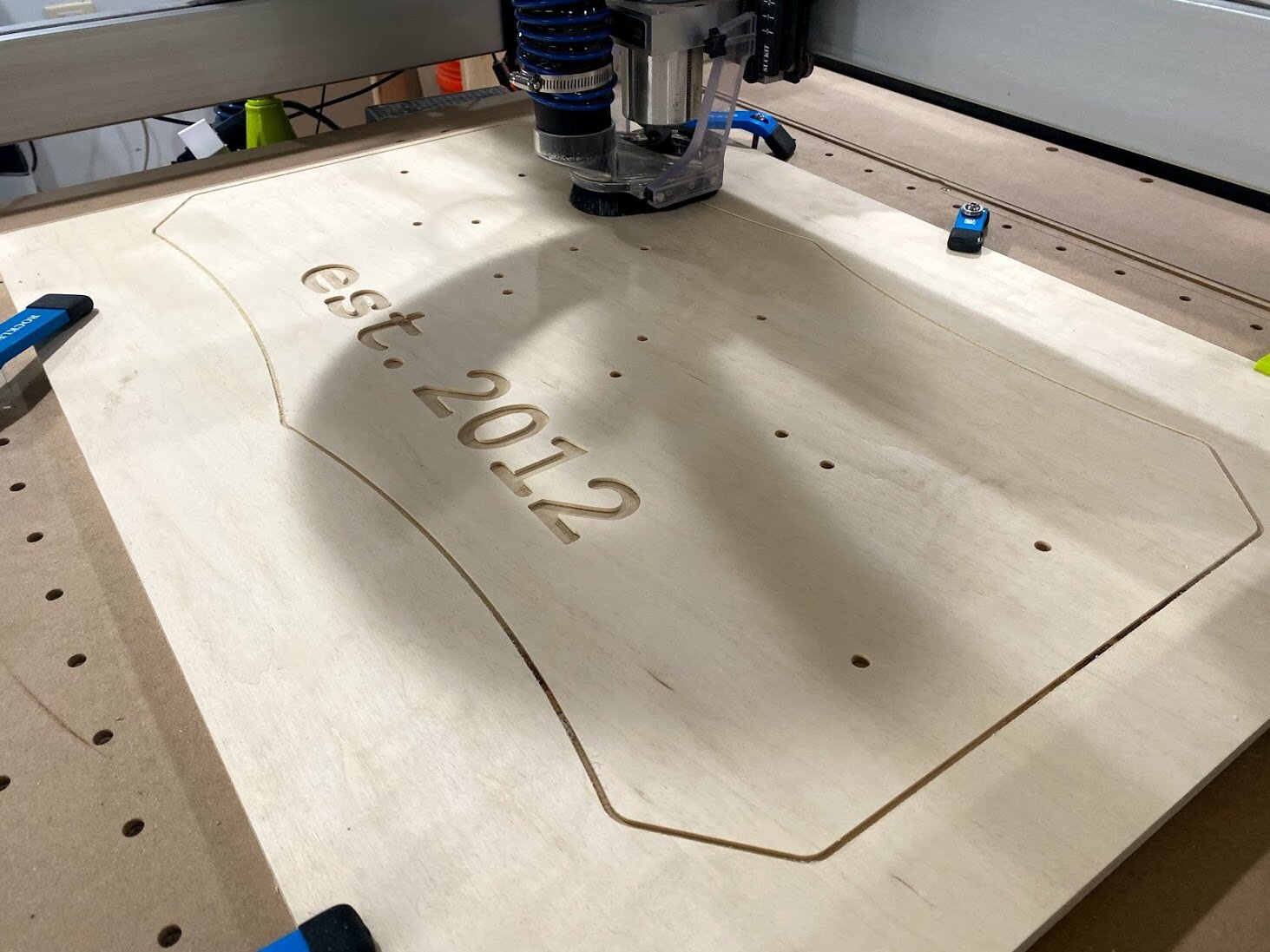

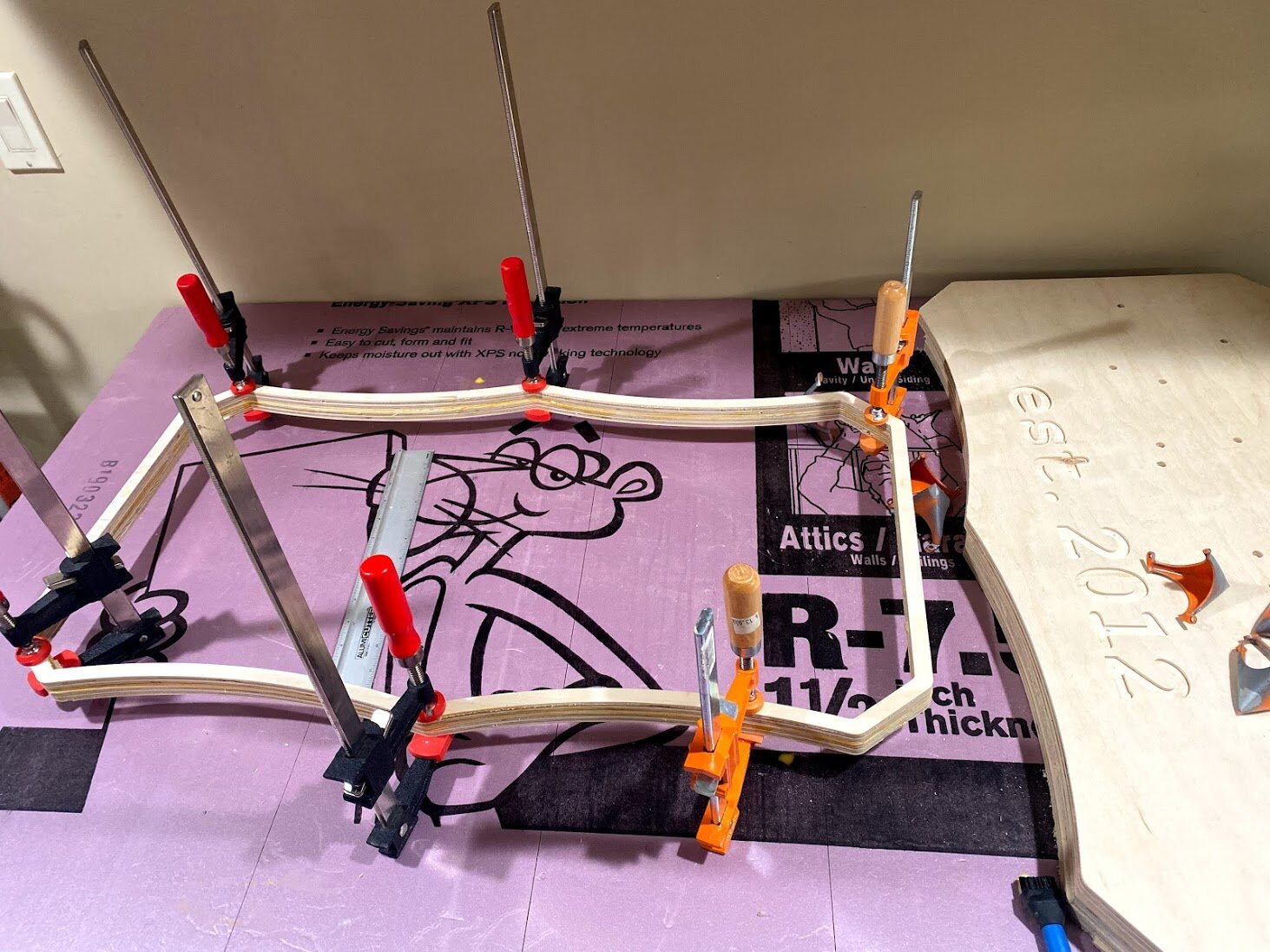

PRODUCTION

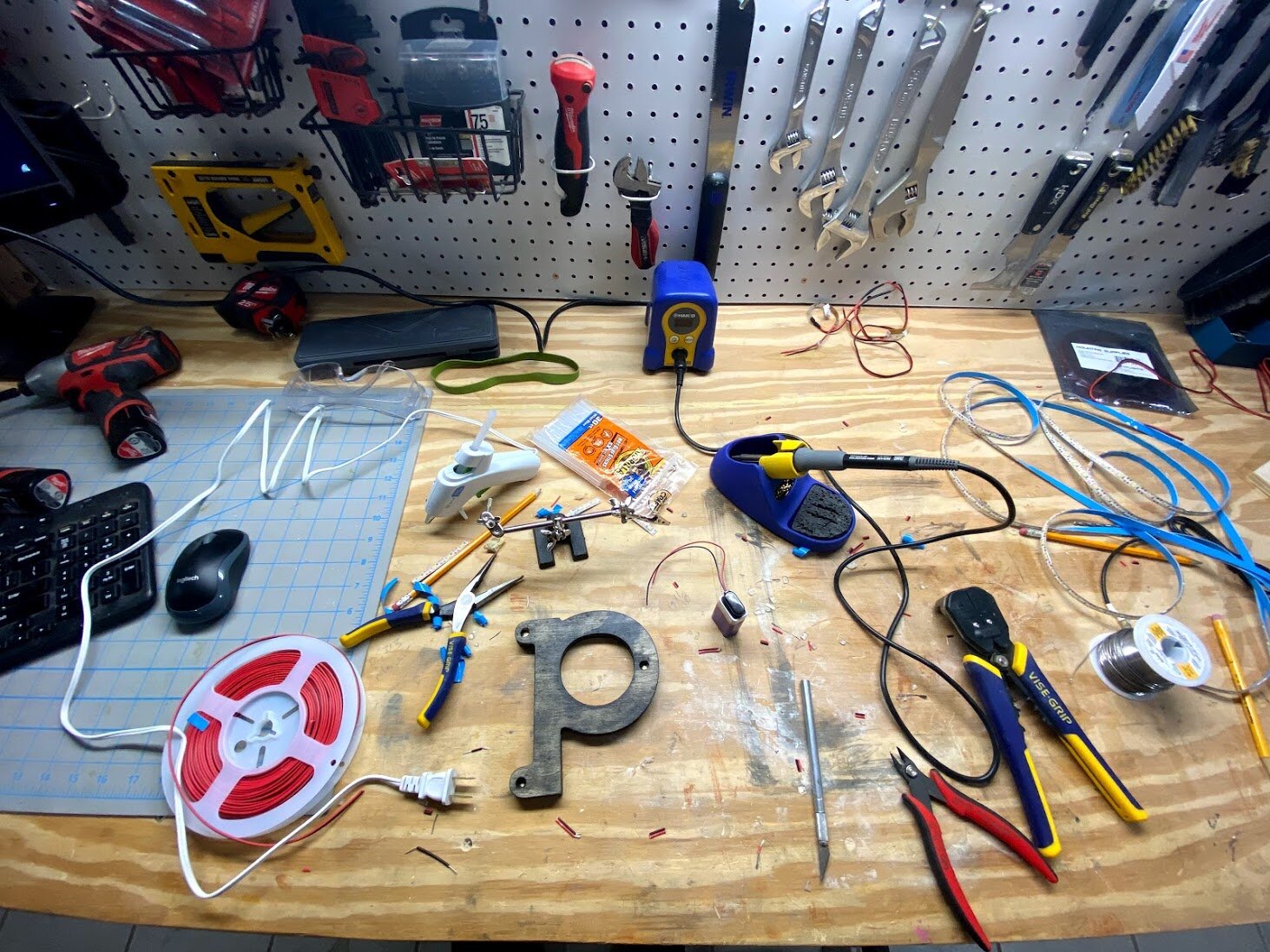

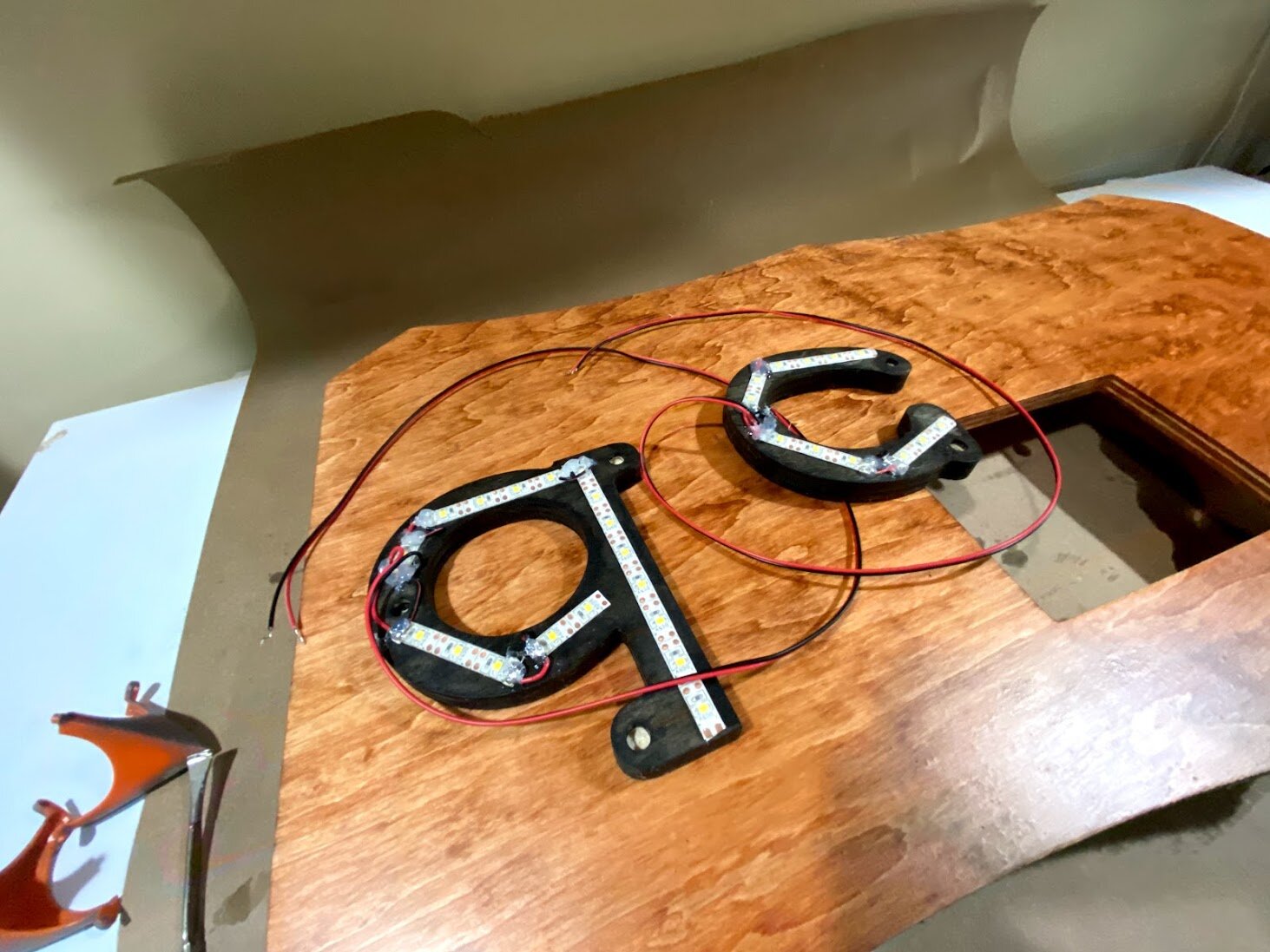

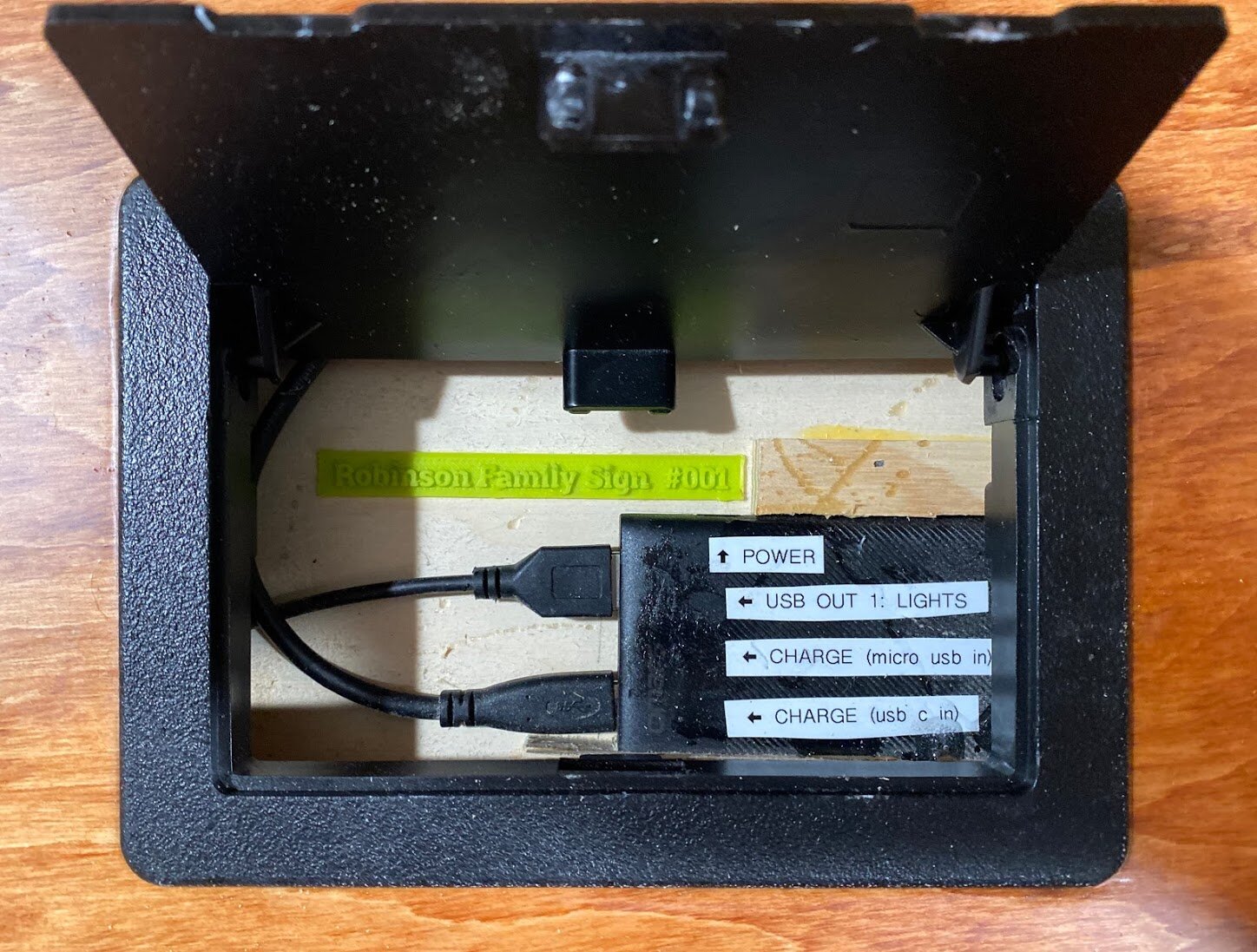

The focus of this article is on the business side of things and not so much a sign making tutorial, so hopefully you’re cool just checking out this slide show of the work in progress. The build was was fairly smooth and I’m happy with how it came out. More importantly, the client was too.

WRAPPING UP (Literally!)

So, as I was finishing this thing, it occurred to me I was going to have to transport it, and ideally, the client would want to gift wrap it so her husband could open it up on Christmas morning. What to do? Then it hit me- this thing is about the size of a 32-40 inch TV. Guess what they sell at Home Depot? TV Moving Kits! It’s an adjustable size box that is the perfect size, along with corner protection foam that would keep it from getting smashed up (it wasn’t super delicate but the lettering was attached with dowels). I shot an email to the client, asking them if they liked they idea and they love it and were cool with me adding it on to the final bill, so that is that weird little ‘box cost” item on the invoice explained. But yeah, a TV moving kit is a great way to transport a semi-complicated sign.